Are you planning to install a durable and efficient metal roof for your property? Understanding the nuances of cutting metal roofing is essential for a successful installation. From tools to techniques, this comprehensive guide explores the intricate process of cutting metal roofing to achieve a precise fit and ensure long-lasting protection for your home or building.

Disclaimer: We strongly advise that you seek professional assistance and consultation for your specific case. Advance Roofing LLC is always available to provide advice and help! For many years, we have been providing Spokane, WA with the highest quality roofing solutions.

The Basics Of Shaping Metal Panels

When shaping metal panels for roofing, several essential aspects must be considered to ensure precision and quality in the installation process:

Metal Sheet Selection: Start by selecting the appropriate metal sheet for your roofing project. Metal roofing sheets come in various materials and thicknesses, providing durability and longevity. Ensure you choose a durable material suited for your area’s weather conditions.

Flat Surface Preparation: Before shaping the metal panels, ensure the working surface is flat and stable. This step is crucial for accurate measurements and cutting. A stable surface guarantees precise shaping, contributing to the overall quality and curb appeal of the roof.

Measurement and Precision: Accurate measurements are critical. Carefully measure and mark the metal sheets to the required dimensions. Utilize tools like straight edges and measuring devices to ensure precision. Proper measurements contribute significantly to a seamless installation process.

Quality Cuts: Use appropriate tools such as shears, snips, or power tools designed specifically for cutting metal sheets. Quality cuts guarantee that each metal piece is shaped accurately, ensuring they fit together seamlessly during the roofing project.

Curb Appeal and Durability: Shaping metal panels meticulously contributes to the curb appeal and durability of the roof. A precisely cut and installed metal roof enhances the overall aesthetics of the property while providing long-lasting protection.

Consider Professional Installation: For complex or large roofing projects, it’s advisable to seek professional help. Experienced roofers have the expertise and tools to shape metal panels accurately, ensuring a successful and durable roof installation.

Understanding the basics of shaping metal panels is fundamental for a successful metal roof installation project. Precise measurements, quality cuts, and the proper selection of materials contribute significantly to a durable, aesthetically pleasing, and long-lasting roofing system for your property.

Factors To Consider Before Cutting Metal Panels

Metal Thickness

When cutting metal panels, consider the thickness of the material. Thicker gauges may require different tools or techniques compared to thinner ones. Understanding the metal’s thickness helps in selecting appropriate cutting tools and ensures a smoother cutting process.

Safety Precautions

Sharp Edges: Metal panels produce sharp edges when cut. It’s crucial to handle these panels with care to avoid injury. Wear protective gloves while handling cut metal to prevent cuts and abrasions.

Safety Goggles: Always wear safety goggles or safety glasses when cutting metal. These protect your eyes from metal shards, dust, or particles that can cause injury.

Metal Shavings and Dust: Metal cutting generates shavings and dust that can cause irritation or respiratory issues. Use a dust mask or respirator to avoid inhaling metal particles.

Protective Coating: Some metals might have protective coatings or treatments. Cutting these metals may produce fumes or gases. Work in a well-ventilated area or wear a mask to avoid inhalation of such fumes.

Safety is crucial when working with metals, especially during cutting, due to the sharpness of edges and the potential hazards of metal dust or fumes. Prioritizing safety measures ensures a secure and effective metal panel cutting process.

Must-Have Tools

When it comes to cutting metal during a roofing project, having the right tools at your disposal is crucial for precision and efficiency. Here are some must-have tools and their functions:

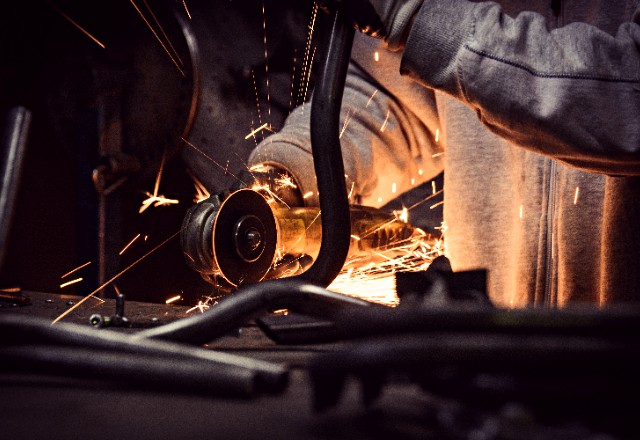

Angle Grinder:

- Function: Versatile and powerful tool for cutting through metal quickly. Its rotating disc is ideal for making precise cuts on metal panels.

- Consideration: Ensure proper safety gear like goggles and gloves due to sparks and debris.

Tin Snips:

- Function: Handheld cutting tools designed specifically for cutting thin metal sheets.

- Consideration: Varying types for straight, curved, or circular cuts. Choosing the right one ensures accuracy.

Metal-Cutting Blade (Circular Saw):

- Function: Designed explicitly for cutting metal roofing panels efficiently and cleanly.

- Consideration: Verify the blade type for compatibility with your saw, ensuring clean cuts without burrs.

Electric Shears:

- Function: Precise cutting tools ideal for making straight and curved cuts on metal.

- Consideration: Perfect for intricate cuts, but might not be suitable for thicker or heavier metals.

Utility Knife:

- Function: Useful for smaller cuts, trimming, and making starter holes.

- Consideration: Ensure a sharp blade to prevent jagged edges on the metal.

Drill Bits:

- Function: Required for drilling holes in metal panels for fasteners or screws.

- Consideration: Use bits specifically designed for metal to avoid breakage or dulling.

Circular Saw Blades:

- Function: Circular saws can also be used with specific metal-cutting blades for larger cuts.

- Consideration: High-tooth-count blades ensure smoother, cleaner cuts.

Each tool has its advantages, but safety should be a primary consideration. Always wear appropriate protective gear, especially eye and hand protection, when operating power tools. Familiarize yourself with each tool’s user manual for proper handling and safety guidelines.

Step-By-Step Guide To Cutting Metal Roof Sheets

Here’s a step-by-step guide to cutting metal roof sheets:

Measure and Mark: Begin by taking accurate measurements of the area to be cut on the metal sheet. Use a straight edge and a pencil to mark the cutting line precisely.

Prepare for Cutting: To prevent any damage to the sheet, support it on a stable and flat surface. Ensure the sheet is clamped securely or held firmly to avoid movement during the cutting process.

Select the Cutting Tool: Depending on the required cut, choose the appropriate cutting tool. For straight, long cuts, use power shears or a circular saw with a metal-cutting blade. For smaller or specialty cuts, metal snips might be more suitable.

Cutting Process:

- Power Shears/Circular Saw: Align the blade with the marked cutting line. With a steady hand, slowly guide the shears or saw along the marked line. Maintain a constant speed to avoid jagged edges.

- Metal Snips: For more intricate or specialty cuts, carefully follow the marked line with the metal snips. For clockwise curves, use right-cutting snips; for counter-clockwise curves, use left-cutting snips.

Safety Measures: Ensure that safety precautions are followed. Wear appropriate safety gear, such as goggles and gloves, to protect against metal shavings and sharp edges.

Finishing: After the cut is complete, inspect the edge for any roughness or jagged edges. If necessary, use a file or sandpaper to smoothen out any imperfections.

Remember, accurate measurements and a steady hand are crucial for precise cuts. Take your time to ensure the cutting process is done accurately and safely, especially when handling power tools or making specialty cuts in the metal sheet.

Seeking Professional Assistance

Seeking professional assistance when dealing with cutting metal roofing is paramount for various reasons:

Precision Cuts: Professional roofers possess the expertise and tools required for precise metal cutting. They ensure accurate measurements, resulting in precise cuts that fit seamlessly, minimizing waste of materials and ensuring every square foot is utilized efficiently.

Experience with Different Roof Types: Professional roofing companies have extensive experience dealing with various roofing types, including tin roofs or other specialized materials. Their familiarity enables them to handle different roof features and structures effectively.

Minimize Material Wastage: Professionals can efficiently calculate the required material needed for the job. They minimize waste by making accurate measurements and cuts, ensuring there’s no need for extra material or overspending on unnecessary supplies.

Quality and Safety: Roofing professionals prioritize safety and ensure all work complies with safety standards. Their expertise guarantees professional-grade results while prioritizing safety measures during the cutting process.

Preserve Integrity of Current Roof: When dealing with an entire roof or a replacement project, professionals ensure that the integrity of the current roof structure is maintained. They can efficiently remove and replace sections without compromising the overall structure of the roof.

In essence, consulting with a reputable roofing company or professional roofers ensures the proper handling of your roofing project. Their expertise and experience lead to efficient and precise cutting, minimizing errors, maximizing efficiency, and ensuring quality results for your entire roof project.

Conlusion

In conclusion, mastering the art of cutting metal roofing is integral to achieving a flawless installation. From choosing the right tools to handling safety measures, each step contributes to the success of your roofing project. Whether it’s for a residential or commercial building, a well-cut and accurately installed metal roof guarantees durability, energy efficiency, and aesthetic appeal for years to come.

509-201-4190

509-201-4190