Homeowner’s Guide

AHEAD OF THE GAME

- Wet spots in the ceiling, which can indicate water leaking in the roof

- Missing or broken shingles

- Decayed or moldy shingles that have lost granules

- Renew the curb appeal

Shingles

Roof shingles are a roof covering consisting of individual overlapping elements. These elements are typically flat, rectangular shapes laid in courses from the bottom edge of the roof up, with each successive course overlapping the joints below.

Mechanical Damage is damage that is done to a roof when a roof is unnecessarily damaged. This is typically caused by a roofing contractor improperly installing the roof or making improper repairs to a roof.

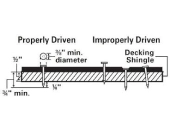

Over Penetrating Nails, many roofers use pneumatic nail guns to nail down the shingles. When the pressure is set too high, the nails simply get driven into the shingles too far. When the nails are overdriven, the heads of the nails punch right through the mat of the shingle.

Fiberglass. If your shingle roof has a shine to it when hit by direct sunlight, it is likely the fiberglass backing is showing on the shingles. When the fiberglass backing begins to shine, it means a shingle is reaching the end of its life

Granule loss which is uniform across the roof is usually a result of normal weathering. Over time, the bond between the granules and asphalt deteriorates, and granules will be loosened and carried away by runoff. Prolonged exposure to hail can also loose granules. Commonly found in gutters.

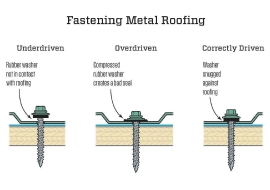

Nailing, drive the nails straight and flat with the shingle surface. Do not break the shingle surface with the nail head. Do not drive nails into knotholes or cracks in the roof deck.

Shingle Layers. Most roof structures are designed for a dead load of one layer of shingles with an extra for snow and a safety margin. However, small and older homes are not structurally sound enough to handle any more immense amounts of burden.

Adhesion simply means how well two materials, or two surfaces, stick to one another. In this case, adhesion means the tendency of a roof coating to stick to the roof’s surface. If the coating peels away, then it means that adhesion has failed to work as intended.

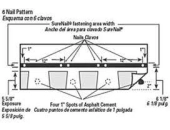

Nail Quantity Per Shingle. Generally, you should use four nails per shingle. For architectural shingles it is 5 – 6 nails per shingle. For high wind areas or when shingles are being applied to a mansard, six nails per shingle are required.

Drip Edge is a metal flashing that is installed at the edges of the roof to help control the flow of water away from the fascia and to protect the underlying roofing components. Drip edge overhangs the sides of the roof and has a small metal flange that is bent away from the fascia.

Underlayment

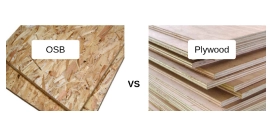

Roofing underlayment is what lies between the shingles and the roof sheathing, or roof deck, which is typically either plywood or OSB. It’s installed directly on the roof deck and provides a secondary layer of protection from the elements, including rain, snow, and wind. It also acts as a protector from condensation.

Synthetic

This type of underlayment is moisture-resistant, and when it’s installed correctly, it offers better protection from the weather compared to felt.

Ice and Water Shield

This underlayment is a waterproof roof underlayment membrane developed to protect vulnerable areas on a roof from ice and water damage. … Ice and water protector products have a modified bitumen adhesive back surface to ensure best water resistance.

Sheathing

The roof deck must be an acceptable substrate: Roof sheathing helps distribute weight evenly across your roof.

Sheathing panels shall meet adopted building code requirements and be, exterior grade plywood or 7/6” (11mm) oriented strand board (OSB).

Sheathing is required when boards are greater than 1/2” apart. Problems with the performance of your roofing system, such as leaks and buckling, increase if installed directly over wood board decks (skip sheathing). Failure to use properly conditioned deck materials will result in deck movement, which will damage the roof covering and may void your warranty.

Likewise, sheathing panels should be supported and securely nailed to all framing members per APA recommendations.

Plywood / OSB. Oriented Strand Board is a widely used, versatile structural wood panel. Manufactured from waterproof heat-cured adhesives and rectangularly shaped wood strands that are arranged in cross-oriented layers, OSB is an engineered wood panel that shares many of the strength and performance characteristics of plywood.

Skip Sheathing is a type of backing that uses widely spaced boards perpendicular to the rafters. skip sheathing is commonly used with wood shingles, which requires OSB/plywood.

Chimney Counter Flashing

Counter or cap flashing is also an L-shaped metal piece, but it is designed to cover the step flashing and embedded into a groove cut in the chimney brickwork. Base flashing is used at the joint between a vertical surface and the roofing surface, in this case the base of the chimney, guarding against water penetration.

Chimney Cricket

Ventilation

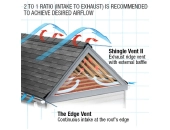

Box Vent also called Low Profile Vents, Louvers, Flat Vents, or Turtle Vents are static vents. This means they have no moving parts. The vent is installed over a hole cut out of the roof. Utilizing natural convection, they create an opening for the rising hot air and moisture to escape through.

InFlow Vent Reduce heat and moisture buildup that can lead to ice damming, roof deterioration and mold infestation. Helps air flow through the attic to manage temperature and moisture. Great alternative if soffit venting is not available.

Ridge Vent is an important part of a home’s roofing system. Installed at the peak of a sloped roof, the ridge vent allows damp, warm air to escape from the attic. A properly installed ridge vent increases energy efficiency and prolongs the life of your roof.

Fascia

Fascia Rot. The rotting condition of the fascia is a sign that water has compromised the structural integrity of the fascia board. There are many factors that can compromise the integrity of fascia boards, but two of the most common are improper installation of drip edge and gutters.

Metal Roofing

Metal Roofing Screws. The standard fasteners are a carbon steel base with plating or coating to provide some level of corrosion resistance. For the optimum protection against corrosion, Long Life fasteners should be used. These are stainless steel and ideal for aluminum panel attachment.

Two easy formulas for determining the amount of metal roofing screws are: Take your square footage and multiply it by 80%. 80 screws for each roofing square. A roofing square is 100 square feet.

Roofing Process

- Day before job starts, an underlayment, Ice and water shield, etc., will be delivered.

- The following morning, about 7am – 10am, an installation crew will arrive to begin the job. The crew will lay down tarps, and if necessary, cover windows and garage door with plywood. As well crew does the best they can to cover and protect bushes and flowers. After setup is in place, crew will begin tear off and installation of plywood/OSB, underlayment, etc.

- Crew does the tear off slope by slope and monitor the weather forecast.

509-201-4190

509-201-4190